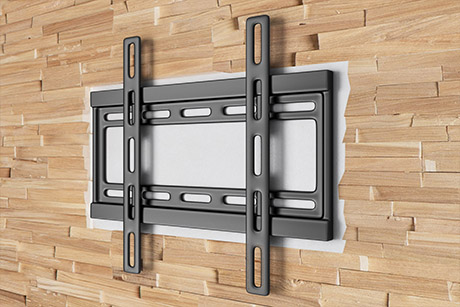

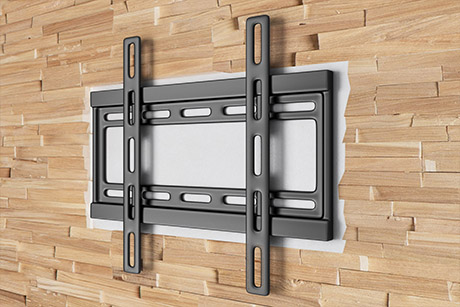

Mounting a TV on Wood Wall Panels: Practical Guidelines

In a modern home, the wall behind the television often serves as the visual anchor of the room. By choosing a natural wood finish—whether it’s smooth reclaimed wood panels or textured solid oak 3D solutions—you bring warmth and deliberate texture into the space. However, to ensure the final result is not only visually pleasing but also structurally stable, it is essential to follow the correct mounting techniques.

The Main Rule: Load-Bearing Structure

The first and most important condition for a safe installation is understanding that wood wall panels are a finishing material, not a load-bearing element. The TV bracket must always be mounted directly into the load-bearing wall—be it concrete, brick, or the wooden framework behind the cladding. This guarantees that heavy equipment will remain stable for years without placing unnecessary stress on the decorative surface.

Mounting Approaches for Different Panel Types

1. Even Surface Wood Panels

If you have chosen flat reclaimed wood panels without significant relief (e.g., Amber, Silver, or MasK models), you can use the classic approach: install the panel first and then mount the bracket through it.

-

Hardware Length: Keep in mind that the thickness of the panel distances the bracket from the load-bearing wall, so screws and wall plugs should be 20–30 mm longer than in a standard situation.

-

Protecting the Material: Before inserting screws into the wood panel, pilot holes must be drilled. This relieves internal stress in the wood and protects the surface from cracking.

2. Panels with Slight Relief (up to 3 mm)

For textured solid oak panels (e.g., OZO or THERMO series), the surface is not perfectly flat. This means the metal plate of the bracket might not have an even support area

- Solution: To avoid deforming the panel when tightening the screws, it is recommended to use thin spacers or washers in areas where the relief creates a recess. This ensures stable fixation and an even distribution of the load.

3. Pronounced 3D Relief Panels (5–30 mm)

When working with deeply structured materials, such as the split oak Deja Vu model or the A Priori and Alias series, mounting through the panel is no longer recommended.

- Craftsman’s Advice: First, mount the bracket directly to the load-bearing wall, and only then install the panels around it, cutting the edges precisely. This method offers the highest level of safety and a visually clean result.

How to Discreetly Manage Cables?

A high-quality wood wall looks best when its overall appearance isn't ruined by visible wires. This step must be planned before installing the panels:

-

Cable Conduit: A pipe built into the wall (at least 50 mm in diameter) will allow you to easily pull wires through, even if you decide to upgrade your equipment later.

-

Free Space Behind Panels: If a batten frame is used to mount the panels, cables can be conveniently placed in the free zone between the wall and the cladding.

-

Connection Points: It is highly recommended to plan all sockets and internet cables directly behind the TV body.

Practical Tips for a Lasting Result

-

Using a Spirit Level: Wood textures and relief lines can be deceptive to the eye, so always rely on the readings of your tool rather than your judgment.

-

Temperature Control: Leave a slight gap between the TV and the wooden surface for air circulation. Wood naturally retains heat, but electronics require ventilation.

-

Future Perspective: If you are installing a medium-sized screen today, leave a small margin in the panel layout around the bracket—this will make it easier to upgrade to a larger model in the future.

A thoughtful approach and precision during the installation process ensure that your natural wood wall will serve for years, maintaining its authentic beauty and structural safety.

FAQ

Can I screw the TV bracket directly into the wood panel?

No, the wood panel serves only as a decorative finish. The bracket must be anchored in the load-bearing wall behind it.

Why do I need to drill pilot holes in the wood panel beforehand?

This prevents the wood fibers from splitting and ensures that the screw doesn't get stuck in the panel but anchors firmly into the supporting structure.

What should I do if the load-bearing wall is made of plasterboard?

In this case, the fixings must be made into the plasterboard frame profiles or by using special heavy-duty anchors, but the safest option is always to find support points in the primary structure.